Achieving supply chain net zero is a parody of The Three Little Pigs. Before anything else, preparation is the key to success, urged Deloitte's senior manager of Risk Management Cathy Lee, who has been dedicating herself to sustainability for more than 17 years.

During her consulting session, the biggest challenge Lee faced was that most of the companies are certainly mindful of the net zero trends, yet not many people felt like they had a plan to follow.

"Question such as 'how can I lower my carbon emissions to 4.2% each year?' has been triggering their fear," Lee said. "People were aware that Science-based Target initiative wanted their carbon emissions to be at 4.2% each year, but no one really knew how to hit it."

In this interview article, Lee shares her insights to "What steps can a company take to achieve net zero supply chain?".

Suggestion 1: Business model pivoting

Taking Deloitte's client, one of the largest cement manufacturers in Taiwan, as an example, its total production of cement and clinkers in Taiwan and Mainland China decreased by 12.6% in 2021. Compounding this, the company's overall sales of cement products in Taiwan and Mainland China declined by 2.9%, according to its annual report.

Due to the decreased demand in Taiwan and Mainland China, this more than 70-year-old cement manufacturer embraces the green transformation and is pivoting its business to waste treatment and the energy industry in response to the circular economy.

In 2021, this cement manufacturer acquired NHOA, a global player in energy storage, e-mobility, and electric vehicle's fast charging infrastructure, and has other related subsidiaries, Energy Storage, an energy storage system provider, and E-One Moli Energy, a battery manufacturer.

"You can always find a novel way to transform your business model, especially if your business can't reach net zero by nature," Lee said. "Our client exemplifies a successful case of business model pivoting. The company's business model is coherent as a whole."

Suggestion 2: Establish a supplier audit program

Lee said, "I think a supplier audit program is necessary because if suppliers don't feel the pressure, your [company's] carbon emission will be increasing continuously."

Many corporations have started hiring consultants with in-depth knowledge about the supply chain. "Not only can they provide the company with information about the environment, society, and governance (ESG), manufacturing processes, and resource materials from their suppliers, but they can also assist the company with restructuring their supply chain in order to achieve net zero," she highlighted.

But some companies like TSMC are not a supporter of the supplier auditing program. They value their suppliers and have commented that it is hard to find out a new supplier who has the same standards and qualities as previous suppliers, she added.

All in all, the choice is in the hands of companies' leaders.

Suggestion 3: Internal carbon pricing mechanism

The Taiwanese government approved a carbon pricing scheme to be implemented in 2030. Lee commented, "It's a powerful tool as it forces the industry to take carbon pricing into their financial considerations. This can lead to lower carbon emissions."

In response to the carbon pricing, Lee advised companies to implement an internal carbon pricing (ICP) mechanism. "However, if a company only takes Taiwan's carbon fee into its consideration, it's not enough," she said.

Some companies may have a presence in different markets, so it could be difficult to determine the carbon fee for each country.

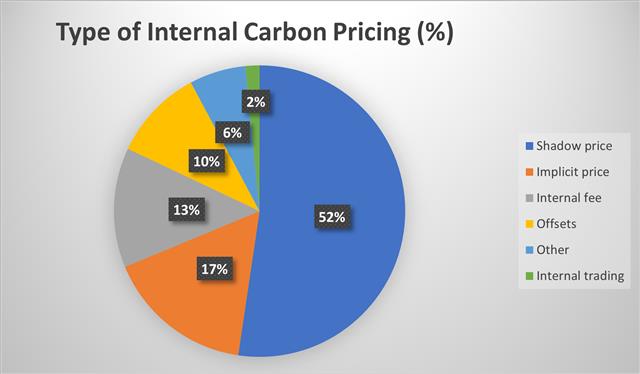

In 2021, 16% of companies that publicly disclosed to CDP already had an ICP, and a further 19% indicated that they planned to implement one in the next two years. In addition, there was a 16% increase in the number reporting the use of an ICP in both 2020 and 2021, according to CDP.

Source: The World Bank. Compiled by DIGITIMES Asia, August 2022

The costs for ICPs range between US$0.8 and US$ 6,000/tCO2e. Most of the companies, however, remain below the US$50-US$100/tCO2e price.

Of the 950 companies disclosing their ICPs to CDP, 68% have a carbon price of US$ 50/tCO2e or below, and a further 18% have a carbon price between US$50 and US$100/tCO2e. The remaining few have prices over US$100/tCO2e.

Lee explained, "The objective of shadow price, for instance, is to reduce carbon internally. When this is simulated, the price may sometimes be underestimated by clients. However, we will guide them to refer to data from The World Bank and some major markets they consider."

"The next step is to decide whether the entire company should use the same carbon pricing system or vary prices based on different business units," she continued. "The conclusion that determines a company's carbon price is whether it is positive and efficient in exploring its carbon pricing range. If it will reduce carbon emissions from its supply chain, then it will be an ideal price."

Suggestion 4: Design a sustainable supply chain program

Lee advised companies to adopt UN Global Compact, ISO 20400, Responsible Business Alliance (RBA), and the Science-based Target Initiative (SBTi) as the sustainable supply chain program's blueprints.

1. UN Global Compact guides companies to create a culture of integrity, companies can not only fulfill their obligations towards people and the planet but also set themselves apart from competitors.

Ten Principles of the United Nations Global Compact | ||

Category | Principle | Description |

Human right | 1 | Businesses should support and respect the protection of internationally proclaimed human rights |

2 | Make sure that they are not complicit in human rights abuses. | |

Labor | 3 | Businesses should uphold the freedom of association and the effective recognition of the right to collective bargaining |

4 | The elimination of all forms of forced and compulsory labor | |

5 | The effective abolition of child labor | |

6 | The elimination of discrimination in respect of employment and occupation | |

Environment | 7 | Businesses should support a precautionary approach to environmental challenges |

8 | Undertake initiatives to promote greater environmental responsibility | |

9 | Encourage the development and diffusion of environmentally friendly technologies. | |

Anti-corruption | 10 | Businesses should work against corruption in all its forms, including extortion and bribery. |

Source: UN Global Compact; Compiled by DIGITIMES Asia, 2022

2. The ISO 20400 standard defines the principles of sustainable procurement, such as accountability, transparency, respect for human rights, and ethical behavior. It highlights key considerations such as risk management and priority setting. It also includes various stages of the procurement process, outlining the steps required to integrate social responsibility into the purchasing function.

3. Responsible Business Alliance (RBA) Code of Conduct establishes standards to ensure working conditions in the electronics industry or industries in which electronics is a key component and its supply chains are safe, workers are treated with respect and dignity, and business operations are environmentally responsible and conducted ethically.

4. The Science Based Targets initiative (SBTi) drives ambitious climate action in the private sector by enabling organizations to set science-based emissions reduction targets.

Suggestion 5: Talent development

Lee shared her concern about talent development. She said, "When we discuss a carbon emission or environmental issue, the majority of people are more geared towards technology and always think about limitations and what is impossible."

"This isn't just an environmental issue. It also has to do with your business development and strategy. You'll need to decide on how you make investments, where you get your funding from, and how your business will evolve in the future," she asserted.

It is crucial that employees understand their role in supporting the company. In turn, they will also know to contribute to achieving the company's goals.

Conclusion

Deloitte Taiwan predicts that data exchange, data accuracy, and carbon emissions performance monitoring will become more and more critical.

When calculating the carbon footprint, many companies are still relying on an outdated database. Deloitte Taiwan believes that they will no longer rely on those old databases and will instead use data provided by the suppliers in the future.

Editor's Note:

Many countries have set a goal to achieve their net zero targets by 2050. DIGITIMES Asia Net Zero Series interviewed major companies, economists, and solution providers to provide companies with complete guidelines to implement their net zero plans.

Cathy Lee, Deloitte's Senior Manager of Risk Management; Credit: Lee