Semiconductor manufacturing is one of the dominant sources of carbon emissions. Vast amounts of power are required to manufacture the chips. Most discussion about the methods to limit global warming focuses on reducing the emission of greenhouse gas (GHG). How do leading chip makers boost their sustainability and minimize the climate impact at the same time?

"Further improvements to reduce GHS is urgently needed; switching the electricity sources to clean energy is also the key." said Sabrina Yu, DIGITIMES Research analyst.

The greenhouse gas protocol defines three scopes of emission:

• Scope 1: direct emissions from owned or controlled sources by the reporting company

• Scope 2: indirect emissions by others from the generation of purchased electricity, steam, heating or cooling consumed by the reporting company

• Scope 3: all indirect emissions (not included in scope 2) that occur in a company's value chain, including both upstream (from suppliers) and downstream emissions (transport, distribution, storage).

According to McKinsey & Company, Scope 1 & 2 account for 80% of a typical semiconductor fab overall emission. Further breakdown can vary by fab, based on various factors including the amount of renewable energy consumption and the implementation of process-gas-abatement systems.

The largest share of emissions for a standard fab falls under Scope 2, accounting for 45%. The major sources include production equipment and facilities/utilities. Scope 1 emissions, accounting for 35%, arise primarily from process gases with high global warming potential (GWP) that are used during wafer etching, chamber cleaning, and other tasks. Additionally, high-GWP heat-transfer fluids used in chillers may also contribute to these emissions by leaking into the atmosphere.

Source: DIGITIMES Research, February 2023

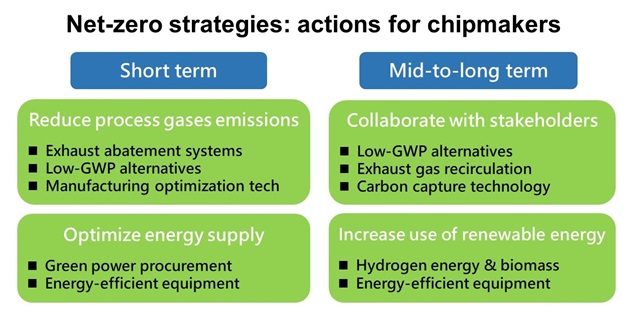

To reach net-zero GHG emissions, the leading semiconductor companies incorporate more sustainable technology into manufacturing processes. TSMC plans to purchase more renewable energy and enhance equipment efficiency at its factories, along with executing more energy conservation projects. Samsung is working to develop carbon capture and utilization technologies to reduce carbon emissions in its research institute. Intel pledges to build new factories and facilities to meet U.S. Green Building Council LEED program standards, identify greener chemicals with lower GWP and to develop new abatement equipment.

Intel said 82% of its energy came from renewable sources, setting a net zero target for 2040, while Samsung and TSMC listed their annual emissions as 20.5% and 9.2% respectively, pledging to reach net zero emissions by 2050.

The world's biggest chipmakers have set ambitious targets to become carbon-neutral in the long run, but turning commitment into practice will be quite challenging. Developing ESG strategies throughout the supply chain, which spans multiple tiers, is another hurdle that must be overcome to achieve those objectives. "To make the chip industry sustainable, we advise semiconductor companies to invest in net-zero technology, explore greener alternatives, embrace innovative solutions and partner with relevant stakeholders." said Sabrina Yu.

About the Analyst

Sabrina Yu received her Technology Management MBA from the National Tsing Hua University and bachelor's degree in Business Administration. She has more than 10 years of research and project management experience at Taiwan-based Chung-Hua Institution for Economic Research (CIER) and AECOM. Currently, her research areas mainly focus on Net Zero/ESG issue, renewable energy and energy storage, and carbon reduction technologies.