As the telecom market moves from 3G to 4G, smartphones require more miniature inductors. A 3G smartphone may only need 15-20 miniature high-frequency chip inductors but a 4G one may require 60-90 pcs. It is therefore imperative to find ways to fit more components in the limited space of a phone or provide more space for batteries by down sizing the component size.

The mainstream size for high-frequency chip inductors has been reduced from 0402 to 0201. Using the traditional process to make miniaturized components will usually lead to poorer product efficiency; and for products to maintain or even improve its efficiency, changes need to be made to the materials or circuit design. While the multilayer inductor traditional process can no longer support the 0201 design, the multilayer inductor via process has become the mainstream because it can achieve higher production precision and smaller internal circuit design through support of virtual software. Therefore, Chilisin, which is capable of manufacturing using the via process, has a great competitive edge.

Chilisin successfully begins volume production using the technologically-demanding via process

The via process is demanding because it uses extremely thin foil. Advanced laser is used to create via holes on the foil and the holes are then mapped onto different positions of the component. Compared to the traditional process, the via process can allow the printing of more varieties of shapes. According to Chilisin's R&D team, different inductor makers may use the same models of equipment, but the difference is how the equipment is tuned, which involves a lot of know-how. The firm spent a lot of energy developing and improving the process and began using it to mass produce inductors in 2008 ahead of its peers.

Among all Taiwan-based inductor makers, Chilisin has the most via process production equipment with a monthly capacity for 400 million units of 0201 high-frequency chip inductors. It plans to expand the monthly capacity to 600 million units in first-half 2015 and 800 million in second-half 2015, as order visibility is clear and demand has been up growing. Currently, via processed products account for around 40% of all Chilisin-made multilayer chip inductors, and the proportion is expected to increase to 70% in the near future.

Downsizing without sacrificing functionalities

Currently Chilisin mainly uses the via process for making multilayer 0201 high-frequency chip inductors (CHQ0603), multilayer power inductors (MPE), and multilayer common mode filters (CMF). Although the size has been reduced, the functions have not been compromised.

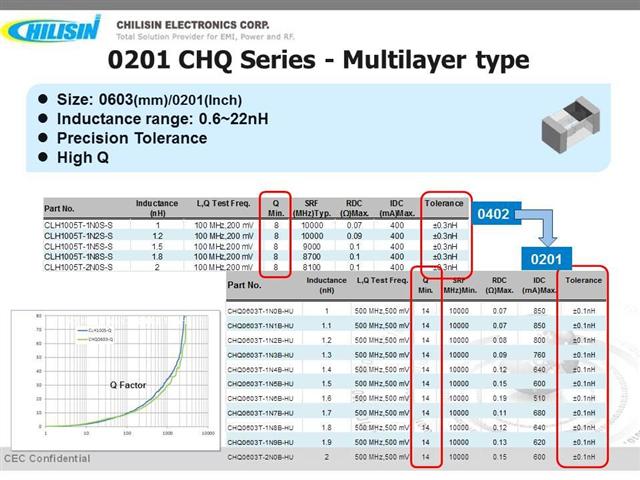

Chilisin's executives noted normally a decrease in an inductor's size will be accompanied by weakened capabilities. But at Chilisin, the via process is enhanced by high precision control and simulation software, plus the internal pattern design. Chilisin can produce 0201 inductors whose functions are comparable to those of 0402 ones. The 0201 inductors have been a major focus of Chilisin's product portfolio in the past two years. Chilisin's CHQ0603 series 0201 high-frequency chip inductors can provide 0.6nH-22nH tolerance with only +/-0.1nH tolerance. The product also has low setting up DC resistance (RDC) and high rate current (900mA max).

Similarly, the MPE series multilayer power inductors produced using the via process has seen a decrease in size, as well as a 30% reduction in RDC with a three-fold increase in saturation current. These meet mobile devices' requirements for smaller-size components with higher efficiency. Chilisin's new multilayer common mode filters have also decreased in size from 2.0mm x 1.2mm to 0.8mm x 0.6mm. In smartphones, common mode filters are used in MIPI interface which can lower transmission noises caused by the screen and camera module. As more and more filters are required in smartphones, miniaturization is inevitable.

The above-mentioned products are mainly supplied to handset makers. In fact, Chilisin has seen breakthroughs in the handset market in recent years. The revenues from this market increased from 16% of total revenues in 2013 to around 25% in 2014. The revenue share will continue to increase in the future.

In-house powder production and flexible process combinations

Chilisin's leadership in via process volume production lies in its capability of making powders of its own. In Taiwan's inductor sector, Chilisin is the only one that has its own powder-making plants and can adjust its powder formulation. The firm can entirely produce its own powders such as nickel zinc (for inductors) and alloys. In addition to being self-sufficient in producing various powders, Chilisin is one of only a few firms that have all the process technologies for producing multilayering, wire-winding molding, one-piece and thin-film inductors.

Chilisin's executives stated that originally, these process technologies were applied individually, but as they matured and advanced, Chilisin began integrating them in preparation for the next wave of demand. For example, the result of combining thin-film and multilayer processes is sub-micron level small-size inductors. Also, the modeling array products rely on a combination of the molding and thin-film processes.

Chilisin has flexible capabilities to combine processes, which means the firm can fast response to demand from various markets. In particular, Chilisin believes NFC is the next big thing in the market. Chilisin's executives noted the company has developed related products and has been working with handset makers. When the market begins to boom, Chilisin can satisfy demand immediately by using its flexible production processes.

0201 and 0402 high frequency chip inductor specifications

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.