Reducing charging time by increasing the power that chargers deliver is seen as critical to overcoming the range anxiety of EV owners, and compared with a high-current solution, increasing the voltage is a more feasible way for upgrading fast charging and will shape the EV industry for years to come, according to DIGITIMES Research.

Jessie Lin, an analyst of DIGITIMES Research, said there are two ways to reach fast charging by increasing power: either increasing the current or increasing the voltage. However, boosting power by increasing amperage has drawbacks, such as more power loss and heat and requiring thicker wire harnesses and cables, therefore increasing vehicle weight and affecting the range performance of EVs

According to Lin, major economies have set rules for fast charging for EV penetration, with the EU and US requiring DC fast charging power to a minimum of 150kW. Meanwhile, China is eyeing a national public charging network that prioritizes fast charging and supplements it with slow charging in its New Energy Vehicle Industry Development Plan (2021-2035).

Lin said that the Tesla Supercharger V3, with its 400V voltage and a current of about 600 amperes, provides a peak charging output of 250kW, but raising the current above 600A makes it difficult to avoid problems with battery or cable overheating as power is the product of voltage and current and more amperage comes with more heat (P=IV=I*I*R). Furthermore, BMS (battery management systems) on batteries may slow charging to avoid overheating, a likely issue arising with increasing amperage.

When the battery temperature rises, the charging power decreases, but under the double-voltage-half-amperage solutions, the decrease in charging power will come at a later time compared with the double-amperage-half-voltage solution, offering a shorter charging time which is critical for overcoming the milage anxiety of EV owners.

Considering that the charging power boost may be achieved by increasing current rather than voltage, raising power does not necessarily reduce charging time, said Lin, adding that that leads the EV industry toward 800V architecture.

Meanwhile, moving to 800V comes with other challenges, despite being easier to overcome than the high-current-low-voltage solutions. BMS and materials have to be improved to prevent batteries from shortening their lifespan. Electromagnetic interference may occur and has to be addressed by a change of design or materials; components such as SiC that can withstand high-voltage of up to 1200V are required; besides, not all EV components can be upgraded to support 800V, such as with air conditioners, and increased usage of DC/DC converter in vehicles is necessary to transform higher input voltage at the source into output at a desired lower voltage.

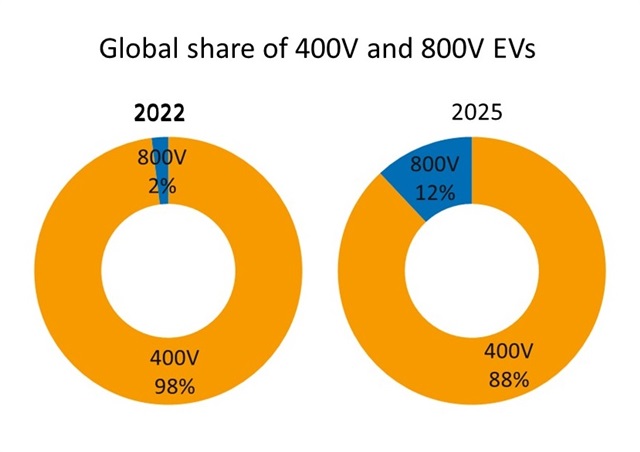

As challenges, such as technological bottlenecks and high costs, may exist for years to come regarding the 800V architecture, it may not become the mainstream product for the mass market before 2030. However, penetration increased rapidly from a relatively low base. According to Lin, premium EVs are the first to come with 800V support. Lin added that the share of EVs supporting 800V is expected to grow from about 2% in 2022 to 12% in 2025, with the remaining primarily 400V EV models.

Credit: DIGITIMES Research

About the analyst

Jessie Lin received a master's degree from the Department of Business Administration at the National Taiwan University of Science and Technology. Her research focuses on automotive, LED, and display panels.