The biotechnology sector is seeing a surge of smart solutions that incorporate information communication technology (ICT) advances to enable biomedical devices to deliver higher precision. This has become a key development trend for the healthcare industry. Having long dedicated to ICT and biotech developments, Taiwan is among the world's leading nations for innovation and technology. If Taiwan can combine its strength in ICT and biotech, it will be able to create unique industry advantages. In view of this, the Taiwan government has been actively driving smart biotech developments by conjoining efforts from the industry, government, academic and research sectors. The result of their efforts is now demonstrated by a firm based in the Southern Taiwan Science Park (STSP).

Fully committed to smart biotech developments in recent years, STSP has fostered a cluster of 78 firms, and its close collaborations with research hospitals has allowed the cluster to build up robust R&D capability. In the wake of the COVID-19 pandemic, biotech plays a critical role safeguarding the world against the coronavirus. STSP's biotech strength thus takes center stage again. For example, Visionatics, an STSP tenant devoted to the development of smart image processing technologies, has created VIVA Vision, a machine vision software library delivering performance on par with the work of leading international developers. Based on its achievements in smart image processing, Visionatics further developed In Vitro Diagnostics (IVD), which provides strong support helping small and medium businesses with limited resources expand into the smart biotechnology sector.

Visionatics targets biomedical applications with VIVA Vision, delivering optimal precision and speed

Visionatics was founded in 2009 at the National Cheng Kung University Technology Transfer and Business Incubation Center. According to Visionatics general manager Klaus Tien, the company has been focusing on computer vision and dynamic image detection and recognition technologies since establishment. In 2013, one year before relocating to STSP, Visionatics began to expand into biotech with a focus on IVD equipment. After the move into STSP, Visionatics continued to engage in image recognition and analysis technologies while strengthening efforts toward machine learning and IoT applications. Visionatics' product offerings now span across AOI, IVD and AIoT. Its achievements in IVD research particularly catch market attention worldwide.

Tien noted that Visionatics' VIVA Vision is the best performing locally-developed machine vision software library. Featuring a complete range of image processing and analyzing functionalities and blazing execution speed, VIVA Vision can detect a target image within one millisecond, at a speed and precision comparable to high-precision machinery. Aside from putting its machine vision technology to use in AOI-enabled manufacturing and semiconductor fabrication, Visionatics has taken the precision up a notch and apply it to molecular diagnostics and immunoassay.

Compared to products on the assembly line, the inspection subjects, such as cells, DNA and proteins, are much smaller, almost on the nanoscopic scale as semiconductors. They also require higher efficiency and therefore simpler detection methods. In view of this, Visionatics introduced a digital magnetic barcode (DMB) beads fluorescence reader for molecular diagnostics and immunoassay as well as a circulating tumor cells (CTC) scanner for CTC detection and diagnosis in 2019. It has also developed proprietary reverse transcription polymerase chain reaction (RT-PCR) to make DNA testing more automated.

Launching second-generation DMB in 2020, enabling simultaneous testing of 384 specimens

Following the launch of the highly-praised DMB device in 2019, Visionatics will introduce the second-generation DMB reader in 2020, featuring an even higher level of sensitivity, throughput, and automation, plus simultaneous testing of 384 specimens.

Commenting on the second-generation DMB reader's high throughput, Tien pointed out that throughput is a bottleneck of existing molecular diagnostics and immunoassay methods and automation is a big challenge. High throughput is one of the compelling features of Visionatics' products. Its first generation DMB reader has been put to use both at home and abroad to quickly test large quantities of specimens, significantly boosting screening efficiency.

Apart from selling its own products through medical equipment sales channels, Visionatics also engages in OEM production for medical device brands. However, as opposed to the conventional OEM production model of most Taiwan-based manufacturers, Visionatics chooses to keep the core technology in Taiwan. It combines its in-house developed software with domestic and international brands' sales channels to create total solutions. For small and medium businesses with limited resources, Visionatics not only helps them build testing platforms but also provides complete software development service to allow them to quickly customize smart vision systems.

Visionatics has performed outstandingly in the global biotechnology scene since its establishment in 2009. Tien attributes the success to the hard work of the Visionatics team and the assistance from the STSP administration and the Ministry of Science and Technology (MOST). Visionatics has received three government grants after relocating to STSP in 2014. These government agencies have consistently supported Visionatics' participation in biotechnology exhibitions while giving Visionatics access to industry information. These efforts have helped drive Visionatics' growth. Going forward, Visionatics will continue to focus on image processing technologies and infuse new energy into Taiwan's biotech development.

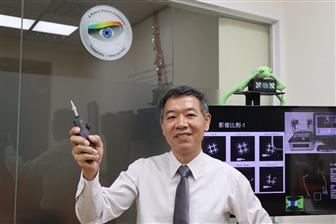

Visionatics general manager Klaus Tien

Photo: Sandy Du, DIGITIMES, May 2020