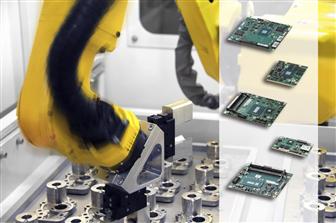

With rising global competition, shortened product life cycles and increasing demand for small-quantity mixed-model production, businesses around the world are endeavoring to accelerate Industry 4.0 development and the top priority is to upgrade traditional robots and machines with intelligent systems. Computer-on-modules (COM) that are at the heart of robot or machine controllers provide the quickest shortcut to an intelligence upgrade.

Industry 4.0 is the dominant trend that has spurred the popularity of intelligent automation and smart factories based on intelligent machines (IM) and intelligent robots (IR). The critical challenge for manufacturers is turning legacy non-intelligent machines and robotic arms into IM and IR that enable computing, measurement, motion control and machine vision to enable customization of products and flexible mass production on the factory floor.

Traditionally, leading machine and robot manufacturers used to develop their own controller boards. However, with new generations of CPUs being launched at accelerated speeds and machine equipment needing to incorporate the latest functions to meet Industry 4.0 demands, manufacturers have had to frequently change their controller board designs. Time delays required for designs to pass certifications also result in increased time-to-market. To circumvent these problems, manufacturers are starting to evaluate the use of embedded COMs as the computing core of customized carrier boards for their control boards. Machine equipment can therefore be upgraded with a simple replacement of the COM with the latest CPU and no need to redesign the entire control board, significantly accelerating the product development cycle.

COM improves development efficiency but also introduces challenges

The COM design model combining the core module and carrier board has the advantage of boosted flexibility but there are still challenges to overcome. First of all, a COM is not a complete single board computer but is the system's core and controls peripheral applications through connections and specialized functionality on the carrier board. In the case of equipment malfunction, the added complexity may make it more difficult to identify the source of the problem from the carrier board, COM or peripheral cards. Therefore, without help of a professional team, locating the root cause can be time consuming.

In addition, manufacturers with ambitions to develop IM or IR solutions tend to engage in projects that are diverse and often involve complex requirements such as firmware changes and BIOS customizations. Support for multiple operating systems including Windows, Linux and RTOS is also required so specific development kits are needed to ensure smooth development of both the carrier board and software. However, as many suppliers are outsourcing a large part of their development work to third-party vendors and have no plan to train their own software engineers, they lack the ability to solve problems independently and promptly provide the necessary technical support.

ADLINK technical team provides on-site support for troubleshooting

A leading international robotic arm manufacturer faced the challenges described above during its transition from internally designed controller boards to the adoption of the COM concept. ADLINK's COM Starter Kits complete with reference designs were able to eliminate most of the customer's problems.

When customers encounter difficulties during development, ADLINK's technical team responds quickly and effectively to assist in addressing system integration issues, whether or not they are directly related to the COM. When necessary, our highly trained staff will visit the customer's on-site location to find the root cause of the problem. ADLINK is always ready to provide professional support to customers during the entire development process.

With regards to R&D, ADLINK has made a significant investment in the establishment of a signal measurement laboratory. All computer input and output signal waveforms can be measured to ensure the COM design and manufacturing comply with the strictest standards. Moreover, complete design for manufacturing (DFM) verification principles are also introduced in the product design stage. All efforts are aimed at guaranteeing the utmost in product compatibility and reliability. ADLINK is also a step ahead of the competition in launching products with a wide operating temperature range to meet a variety of challenging customer requirements.

ADLINK provides complete solution with one-stop design and manufacturing

With the exception of printed circuit boards, ADLINK develops its COM products independently from scratch, from design to manufacturing, and therefore has the ability to meet a wide range of customer requirements, including firmware changes and BIOS customizations. Comprehensive support is provided for Windows, Linux, VxWorks and QNX operating systems, drivers and board support packages (BSP). Also available reference carrier boards and a wide range of interface conversion kits to speed up the development process for customers.

ADLINK is among the world's five Premier Members of Intel® Internet of Things Solutions Alliance so it has the advantage being able to deliver early sampling, leading competitors by over two months. ADLINK is also able to launch new COM products that keep up with every new generation of Intel processor, allowing customers to integrate the latest technologies into their control systems.

In summary, the rapid rise of the Industry 4.0 trend is driving a booming market demand for intelligent machines and intelligent robots. Manufacturers of IM or IR solutions are joining efforts with the ADLINK COM team to accelerate the introduction of a wide range of intelligent automation applications, bringing the smart Industry 4.0 initiative closer to reality.

The COM design model combining the core module and carrier board has the advantage of boosted flexibility

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.