The excitement sparked by Apple iPhone's touch screen has created much hype about projected capacitive touch technology. However, in terms of market share or applications, projected capacitive touch is not as popular as resistive touch. Therefore, despite projected capacitive touch's advantages, such as multiple-touch, gesture recognition, response time, sensitivity, durability and optical properties, it is necessary to rationally analyze what possible effects these features may have on the overall touch performance. Issues that need to be addressed are as follows:

1. How to judge touch performance? Is there any criterion?

2. What is the difference when projected capacitive touch is applied to panels of different sizes? The difference between small-size panels, (3.5" and 4.3"), medium-size (7", 8" and 10.1"), and large-sizes (12.1", 13.3", 15" and bigger).

3. In order to minimize noise, how do we carry out system integration and integrate individual modules (PCB & wiring materials) with touch panels as a whole?

4. Environmental factors. How to work around them?

5. Others

For system integrators, the above mentioned are closely linked to the viability, implementability and complexity of a touch technology, and of course these form a cost issue.

This article will address certain challenges and problems that system integrators would be confronted with when designing/implementing projected capacitive touch. Overlooking them or leaving them unsolved may result in serious problems giving rise to poor touch performance or even malfunction.

Articles regarding projected capacitive touch technology can be found in many magazines, newspapers, websites and documents from various touch panel makers/vendors. For consistency, this article will deal only with the working principle of projected capacitive touch. For more details about it, please refer to the various possible sources mentioned above or visit AMT's website at http://www.amtouch.com.tw/.

Let's look at the illustrations below, which can be found on AMT's website | Projected Capacitive Touch Screen | Basic.

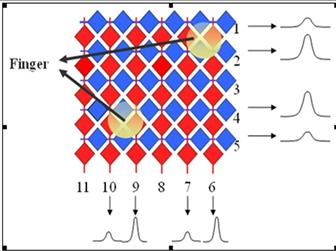

Figure 1

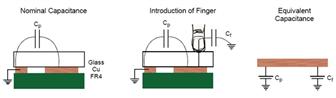

Figure 2

Figure 1 shows the interleaving electrode patterns and the signal acquisition of an average projected capacitive touch panel. In short, the electrode layers respectively marked in red and blue and oriented orthogonally to each other will charge or discharge their own axes. And theoretically, the values of the capacitances are much close to each other when the touch panel is not touched. However, the yellow-marked parts in Figure 1 show that when the touch panel is touched by a finger or contacted with a conductive object, the capacitances will change, and the touched position can be located by measuring the capacitance change.

There are several ways to trigger and measure the capacitance change of a projected capacitive touch panel such as by interleaving measurement based on the property of triggered signals. With capacitance measurement and consideration of panel structure, functions such as single-touch and multiple-touch can be realized, and Ghost Point can be eliminated. (Please see related published articles for details.)

The inclusion of a projected capacitive touch screen into a system requires the following sub-systems:

1. A projected capacitive touch panel

2. Touch controller or control board, which is connected to the system and controls the touch panel.

3. Firmware: A control software that is embedded inside the control board.

4. Driver: The program that is installed on the system to interact with the firmware.

System integrators should at least be aware of the following:

1. Mechanical design, which underlies the firm installation of the touch panel, control board, and wiring.

2. Touch kits placement inside the system, which should minimize the interferences from other internal devices.

As the capacitance change that a human finger can trigger is merely a few pF (pico Farad), not only the measurement accuracy is important but also the treatment to those unfiltered signals plays a decisive role for the performance of a projected capacitive touch. Such treatment should include signal processing, noise immunity against interferences and the algorithm of control firmware. And as the differences between single-touch detection and multiple-touch detection have something to do with the algorithm of firmware, the system integrators have the following issues to consider:

1. Basic touch performance

Regarding signal transmission, although the report rate decides the touch performance, the "quality" of signal transmission cannot be underestimated. For example, the touch performance would not be good enough even if the report rate is high.

The touch performance concerns the percentage of the normal signals that are correctly read and analyzed through measuring the self-noise and a variety of noises spurred by the environment surroundings. Basic touch performance is the basis for calculating the "effective signals."

To improve basic touch performance, what system integrators can do are:

- Observe the signals when the panel is not touched, so as to analyze how a noise is interpreted as a signal.

- Observe the signals triggered by the touches on specific touch positions for the same time length, so as to analyze how noise is triggered.

- Take a straight line drawing test and curve line drawing test with the same speed rate, so as to analyze how noise is triggered and also the linearity.

- Observe multiple-touch performance, touch-zone differences and inspect certain properties.

In conclusion, before a touch panel can be integrated with the other parts of a system, the basic touch performance must be enhanced to certain standard.

2. Size versus touch performance

Between capacitance reading and algorithm, it is not proportional but forming a complex geometrical progression based on panel sizes, report rates and some other factors. Knowing this is very important because it will help system integrators with selecting and combining touch IC and adjusting firmware performance, and further defining the overall touch control performance. For bigger panel sizes, since the materials selection and wiring layout are more demanding, the system integration of bigger panel sizes is generally more difficult than that of smaller sizes. It is thus better to gradually include each subsystems into the system one by one and step by step while also seeking the assistance from testing instruments more often. As mentioned in the "basic touch performance" section, it would not be hard to find the solution if system integrators act cautiously.

3. Noise

System integrators must be prepared for "debugging." A noise that does not make much impact on an ordinary digital circuit often causes a projected capacitive touch screen to false action when contacted by a human finger. Noise has always been the formidable enemy of projected capacitive touch.

System integrators should first understand that the objects noise can possibly interfere cover the touch panel, touch controller, wiring material and so on. And for a projected capacitive touch system, there are quite many noise sources in the system to impact the touch panel. To overcome it, system integrators can first focus on the power supply, the wiring/circuiting and also on the surrounding low-frequency electromagnetic waves because resolving them will substantially smoothen the system integration. And of course the debugging varies from case to case. But remember not to damage the signals when eliminating noise since they are almost in the same scale and needs extra care.

4. Definition of operation environment

It is a very interesting question to ask if a projected capacitive touch screen can function well when having water on the surface. The answer is possibly yes, yet on conditions. As it has been resolved for a projected capacitive touch screen to work with water drops on the surface, system integrators need to know the operation environment for his product to make correct selection of touch technology. Generally speaking, the performance a projected capacitive touch product is subject to panel sizes, sensitivity, panel thickness, humidity, power supply and low-frequency electromagnetic waves.

And of course the countermeasures differ from case to case.

As it is beyond the reach of this article to fully reflect the actual situation of every matter concerned, system integrators would need to pay more attention and caution when seeking for appropriate solutions. This article aims to address the matters needing attention for projected capacitive touch system integrators. From this article, it is not hard to find that it in fact requires an overall product view to develop a projected capacitive touch system. And the key to fulfill this requirement is a professional touch panel manufacturer that specializes in touch total solution. Apex Material Technology Corporation has put in a lot of efforts in projected capacitive touch technology and is very experienced in providing touch total solution. At this moment when various projected capacitive touch applications emerge on market, AMT hopes this article can offer a few references that might be meaningful to system integrators. (AMT website: http://www.amtouch.com.tw/ )

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.