NeoGene Tech, a Guangzhou-based technology platform provider of designing and fabricating ultra-thin vapor chamber devices for 5G smartphone application, has announced its Level 3 PWS (Print Wick Structuring) COMBO technology has overcome the bottleneck and limitation of traditional copper mesh wick technology in two-phase working fluid transportation and circulation efficiency inside a big-area and super-narrow-space vapor chamber device.

Up to date in the industry, the thickness of vapor chamber in production for smartphone applications is still at over 0.3mm, NeoGene said. Most smartphone brands keep seeking advanced technology among their supply chain to pursue vapor chamber devices as thinner as possible. The thickness of vapor chamber at 0.2mm as well as device area at over 5,000mm2 is always the dream to the industry since thermal management issue will become more critical as never before.

NeoGene cited industry experts as noting that the space of liquid channel and vapor channel inside the vapor chamber will be tremendously limited totally at only 100um if the device thickness is just at around 200um. Once the distance between the evaporator and the condenser is too far and device area is too wide, it is almost mission impossible to accommodate an appropriate thinner copper mesh wick structure and to have enough vapor space as well to ensure that the two-phase working fluids can be efficiently transported and circulated inside the device to enable the device keeping acceptable thermal performance.

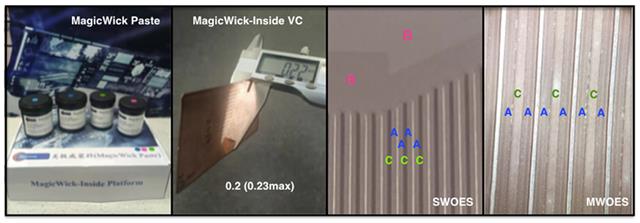

"Based on our MagicWick-Inside Technology Platform, the Level 3 PWS COMBO technology adopts selective screen printing technics and co-sintering processes to make three different MagicWick structures with different thicknesses and patterns in order to perform different functions in different flow channels and regions simultaneously," said Jeffrey Chen, CEO of NeoGene Tech.

"Three different kinds of MagicWick paste materials (MW-A, MW-B, MW-C) were screen printed in different area on etched copper alloy substrate and were baked to form the SWOES (Semi-Wick-On-Etched-Substrate), and then proceed to become the MWOES (Magic-Wick-On-Etched-Substrate) before device packaging process. Different from PWS Level 1 and Level 2 technology, PWS COMBO technology is a way of solving different limitation issues simultaneously inside an ultra-thin and ultra-big vapor chamber by having a novel flow channel design and combo wick structuring. It is very easy to conduct the multiple wick structuring processes in mass production by adopting automatic screen printing and baking technique and continuous decomposition and sintering furnace," said Chen.

"The Level 3 PWS COMBO technology is actually an ultra-thin vapor chamber design and fabrication approach for laterally balancing the efficiency of liquid channels and vapor channels in ultra narrow space. By having novel flow channel design and different magic paste recipes, the MagicWick-Inside VC devices made by Level 3 PWS COMBO technology with thickness at only 0.2mm (with +0.02 tolerance) and the size at 5000mm2, can be working very efficiently at 5W, and the surface temperature difference (delta T) between evaporator and condenser with distance at 70mm is measured at around 2 degrees C. Thanks to the collaboration of MagicWick A (wick thickness ~35um) in liquid channels and MagicWick C (wick thickness <10um) in vapor channels, the anti-gravity transportation speed of liquid working fluid from condenser to evaporator is measured at over 20mm/sec," added Chen.

NeoGene Tech's authorized thermal module maker, Jieqiao Electronics, will be the first player to adopt PWS COMBO technology in 0.23max big-area vapor chamber mass production, and this technology will be also opened for all thermal module makers once the MagicWick-Inside Technology Platform license program is reached and conducted accordingly, according to Chen.

Photo: NeoGene Tech