Artificial intelligence (AI) technologies play a critical role driving the transition to Industry 4.0. In particular, their use in combination with machine vision has become the first step that most manufacturers are taking to incorporate smart systems into their production process. By leveraging deep learning algorithms, machine vision systems can learn by themselves to determine the quality of the device under test. However, there are certain barriers to overcome before manufacturers are able to make use of AI technologies, according to Kai-Hsiang Hsu, senior product manager, smart machinery business and product center, ADLINK. To help manufacturers make a smooth transition to smart manufacturing, ADLINK has introduced AI-enabled machine vision solutions developed by combining its accumulated strength in machine vision and AI. ADLINK's plug-and-play (PnP) solutions make it easy for manufacturers to make the first move toward smart manufacturing.

AI technologies are mainly used in the manufacturing sector for machine vision and robotic arms. Deep learning algorithms are being used for predictive maintenance of production equipment, optimization of production efficiency and improvement of product quality. Taking the PCB and the plumbing parts sectors for example, Hsu noted PCBs are printed with fine and intricate circuits and are produced at a rapid rate. Plumbing parts are characterized by curved surfaces. AI technologies will be the key to enhancing inspection system efficacy for the two types of products as they require high-performance inspection systems. Aside from examining items on the production line, AI-enabled machine vision systems can also be used for factory management, for example, to perform image analysis on factory floor operators to ensure labor safety or recognize objects in the factory to help control the work environment for better management efficiency.

With AI's strong performance and diverse applications, manufacturers largely agree that AI will be the way to go. However, when attempting to incorporate AI, most manufacturers will find a gap between idea and execution. ADLINK assistant manager Chia-Wei Yang pointed out the challenge is that AI is not just a device equipped with accelerators but a complete hardware and software architecture implementing highly-specialized know-hows such that AI-enabled machine vision systems are intelligent enough to achieve smart manufacturing.

Extending on Yang's view, Hsu talked about proof-of-concept (POC) systems of AI-based machine vision emerging on the market in recent years. With their current model training process, they have been unable to meet expectation when put to practical use on the factory floor. This is mainly due to a lack of professional know-how. According to Hsu, successful AI implementation requires both industry-specific know-how and AI expertise. Each specialty of manufacturing has its own unique production process and every factory has different production equipment. Every piece of new machinery including AI-based systems needs to work in synergy with the existing equipment and production model. However, most AI system providers lack a full grasp of industry-specific knowledge.

As to AI systems, it requires highly specialized expertise to build a system with an ideal hardware and software combination best suited to the production line. According to Hsu, neural networks carrying out deep learning algorithms are very complex. On top of that, the different AI accelerators designed by leading chip makers, including Google's TPU and NVIDIA's GPU as well as Intel's and AMD's AI processors, may deliver different performances on the same neural network due to their individual characteristics. As such, AI system developers not only need to know about deep learning and neural networks but also fully understand the features of AI accelerators on the market so as to come up with the best solution that meet the system requirements while working with the end equipment in accordance with expectation.

However, to build up the manufacturing know-how and AI expertise needed to implement a precise AI-enabled machine vision system requires tremendous resources and time. Engaging professional third-party vendors will be a smart move to most system developers and manufacturers. Ming-Chang Kao, R&D manager, industry platforms, ADLINK, noted starting out as a provider of automation solutions, ADLINK has built up extensive experience and knowledge in the manufacturing sector. ADLINK also has established an AI team long dedicated to the R&D of various software and hardware solutions so it is capable of designing tailor-made AI-enabled machine vision solutions for all kinds of manufacturing specialties.

Kao added that with a full understanding of deep learning algorithms and hardware accelerators on the market, ADLINK can put together an AI-enabled machine vision system that closely matches customers' production line needs and thereby boost the operation success rate on the factory floor. Furthermore, ADLINK provides a highly integrated hardware and software solution, allowing customers to make a one-stop purchase of an all-in-one system. The plug-and-play system is ready to use, helping manufacturers quickly get the system up and running, calibrate the parameters at any time and flexibly reconfigure the production line. ADLINK's machine vision solution perfectly meets manufacturers' every expectation.

ADLINK's AI-enabled machine vision solutions have been used in manufacturing systems at home and abroad. According to Che-Hsian Huang, CEO of LEDA Technology, a close partner with ADLINK, on top of its years of experience in machine vision, ADLINK is making additional efforts toward AI research in recent years. With a dedicated AI team, ADLINK is able to design hardware products that quickly satisfy system vendors' needs so that system vendors can focus on developing the algorithms. ADLINK's team of experts also offers consultation services to customers to help with their system design and shorten their development cycle. ADLINK is committed to assisting manufacturers as they make the first step on the transition to smart manufacturing.

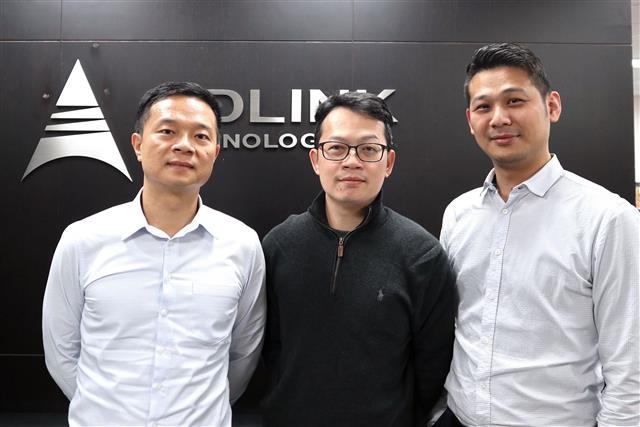

ADLINK assistant manager Chia-Wei Yang (right), senior product manager Kai-Hsiang Hsu (middle) and R&D manager Ming-Chang Kao (left) talk about ADLINK's extensive experience in AI and machine vision and how its solutions can help customers quickly build up smart systems

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.