The race to thinner devices with high performance pushes the advanced packaging industry toward smaller form factor and thinner packages, some as small as a just a few hundred microns (less than 0.3 mm) in height. To accommodate this rapid miniaturization, we are seeing a growing number of trends to improve existing processing techniques.

One such trend is the utilization of inkjet technology to replace traditional engraving techniques for package marking via a fully-additive non-contacting deposition method. When executed correctly, inkjet marking offers equivalent permanence to traditional engraving techniques to protect against fading or peeling but completely offsets the risk of the heat damage to the IC chip inside the semiconductor package. As an added benefit, this flexible, cost-effective solution also provides faster and clearer printing over the conventional method of engraving through laser cutting.

Orbotech Ltd., a leading provider of digital production solutions for the micro-electronics industry, offers a cutting-edge inkjet printer designed to answer the needs of the IC packaging market. "We have developed our inkjet printer to exceed the market's demands," said Arik Gordon, Orbotech's Printed Circuit Board Division President. "Orbotech Inkjet 500 is on site at several leading Advanced IC packaging manufacturers and is currently being utilizing for a range of cutting-edge applications." Orbotech is also currently working in cooperation with several leading ink and chemical R&D centers on the latest cutting-edge developments for the consumer electronics manufacturing industry.

Orbotech's patented DotStream Technology directly prints the ink onto the substrate using an innovative inkjet chemical deposition control. This ensures accurate pattern printing and efficient bond formation between the ink and the chip surface.

Printing and ultraviolet irradiation are carried out simultaneously to solidify the ink to the package surface. This permanent adhesion process not only guarantees safety of the chip, but also longevity of the package by eliminating peeling or fading.

"As the need for smaller electronic components increases at an unprecedented rate and in parallel the demand for smaller and thinner Advanced IC packages increases, conventional marking techniques pose a high risk of damaging the IC chip inside the package," explains Micha Perlman, General Manager of Orbotech's Italy-based inkjet development and production center. "Orbotech's Inkjet 500 offers a smarter and safer CAM-ready alternative to traditional laser marking for permanent legends and 2D barcode marking with higher contrast and clearer resolution."

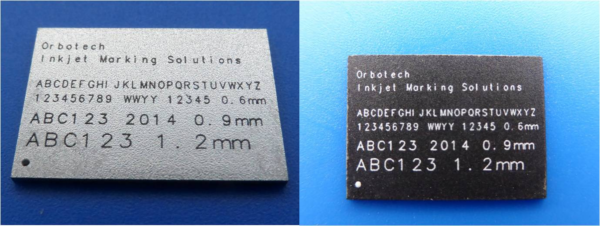

This flexible system supports a wide range of ink types and guarantees unmatched adhesion for a large variety of ink types to ensure easy, scalable manufacturing processes that are simple to manage. DotStream Technology provides advanced drop control and utilizes sophisticated algorithms for digital data optimization and optimal drop distribution per pixel for precisely accurate results. High registration accuracy (±35 μm) supports high-contrast printing of small character sizes (down to 0.3 mm) across a large range of font types for optimal clarity. This ensures that the process is not only safer, but also produces cleaner and clearer high-resolution and high-contrast permanent markings.

This flexible system supports a wide range of ink types and guarantees unmatched adhesion for a large variety of ink types to ensure easy, scalable manufacturing processes that are simple to manage. DotStream Technology provides advanced drop control and utilizes sophisticated algorithms for digital data optimization and optimal drop distribution per pixel for precisely accurate results. High registration accuracy (±35 μm) supports high-contrast printing of small character sizes (down to 0.3 mm) across a large range of font types for optimal clarity. This ensures that the process is not only safer, but also produces cleaner and clearer high-resolution and high-contrast permanent markings.

Fully-additive non-contacting inkjet printing now guarantees high-contrast permanent ink adhesion while protecting the chip inside the package

Example of Orbotech Inkjet 500's high-contrast, clear results across a range of character sizes (down to 0.3 mm)

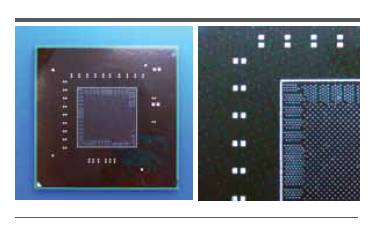

Example of underfill dam printing using the Orbotech Inkjet 500

DIGITIMES' editorial team was not involved in the creation or production of this content. Companies looking to contribute commercial news or press releases are welcome to contact us.