The world has come to a consensus over the importance of developing renewable energies to mitigate the greenhouse effect and decrease our over-reliance on fossil fuels. In particular, solar energy has risen to become one of the primary methods of power generation. However, the relatively short life cycle of solar PV panels, which is approximately 20 years, has resulted in the accumulation of waste PV panels awaiting processing in many countries. According to a model by the International Energy Agency (IEA), 365 million tons of waste PV panels will be generated globally by 2050; as a result, the recycling of end-of-life PV panels has become an urgent issue.

TSGC co-founder and CEO Andrew Hung states that countries such as the U.S., EU, and Taiwan have been long concerned about the massive amount of waste PV panels that would undoubtedly be generated by the promotion of solar energy, and have already established regulations for their processing. California, for example, defined end-of-life PV panels as general waste in 2021 to simplify the recycling process while also severely restricting their methods of recycling by prohibiting chemical and thermal processing. TSGC's PV Circulator solution for waste PV panels features fully automated physical disassembly and is expected to begin operations in California during Q4 of this year.

TSGC founder, professor of the National University of Tainan Department of Greenergy, and director of the Solar Energy Center Yaw-Shyan Fu points out that the governments of many countries are utilizing subsidies for recycling companies to handle tasks such as disassembly and sorting. However, the actual benefits are limited to decreasing the amount of trash. In response to the sustainable development trends in recent years, the concept of circular economies has emerged, encouraging sectors to willingly manufacture products using recycled resources to meet ESG guidelines. As such, TSGC's PV Circulator solution has attracted broad interest.

Automated Disassembly of PV Panels—Recycles Nearly 100% of Waste Materials

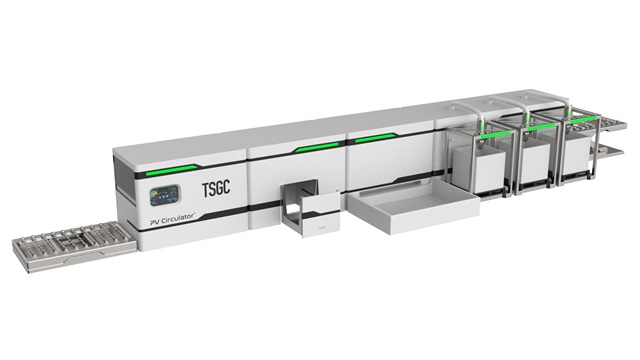

TSGC was founded in 2022 with support from the Ministry of Education and National Science and Technology Council to focus on solving the environmental impact caused by waste PV panels. The company developed the world's first fully physical and automated PV panel recycling technology and applied it to launch the PV Circulator. The product is capable of disassembling each layer of PV panels under room temperature through methods such as automatic sorting and milling without requiring heat, water, or chemicals. Materials such as aluminum frames, glass, cell, EVA, PVDF back-sheet, and precious metals can be recycled intact.

TSGC integrated their exclusively developed artificial intelligence and Auto ML (automatic learning) technologies into the PV Circulator. Vision AI recognizes tens of thousands of global PV panel specifications, which are then applied to automatically disassemble PV panels; data such as recycling rate, power consumption, and emission reduction are automatically uploaded to a cloud platform. Finally, the equipment utilizes Web3 technology to automatically generate a free recycling resume to the owner of the end-of-life PV panel, which in addition to documenting the clean recycling, can also act as evidence to the implementation of ESG strategies.

Andrew Hung states that while there are various solutions, such as the heated blade method and pyrolysis tunnel recycling method developed by Japanese companies NPC and Shinryo as well as the EU FRELP, available in the market for recycling waste PV panels, all of them involve chemicals, heat, or landfill, which carry different degrees of environmental impacts. In comparison, TSGC's solution not only features a high recycling rate, high capacity, and zero pollution, it also meets California's latest regulations, does not require chemicals, water, or heat, and surpasses the 80% recycling rate mandated by EU's Waste from Electrical and Electronic Equipment (WEEE).

"Considering the extremely high costs for European and North American countries to transport waste PV panels, we launched a mobile version that can immediately begin on-site recycling. For example, a 500MW site in California can save nearly $2 million in transportation costs to a recycling plant 500 miles away." Yaw-Shyan Fu explains, "Given that European, American, and Japanese markets lack the technology and industry chain to recycle and reuse plastics of PV panels, TSGC has developed a technology that upcycles plastic and has partnered with Taiwan's industry chain to provide a global material upcycling service. Upcycled plastics can be used for value-added manufacturing of regenerated sneaker soles."

Strategic Deployment in the U.S., Taiwan, and Advancement into the European Market

Since its founding, the unique PV panel recycling technology developed by TSGC has won multiple recognitions, such as the InnoVEX 2023 ESG & Green Tech Award, SelectUSA Investment Summit 2023 CleanTech, top 10 of the 2023 Intersolar Award, top 10 of VivaTech x TotalEnergies, and top 10 of VivaTech's Coup de Coeur.

Andrew Hung states that throughout the company's development, their long-term partner TTA has provided multiple startup training courses, expert/industry mentoring, and led TSGC in attending major exhibitions and competitions such as CES and VivaTech. These efforts have greatly increased the international reputation of TSGC and created many business partnership opportunities.

Aside from focusing on the U.S. market, TSGC is simultaneously dedicated to developing the Taiwanese and European markets. In Taiwan, TSGC has partnered with professional licensed waste disposal companies and plans to install PV Circulators in the northern, central, southern, and eastern regions of Taiwan. It is anticipated that the establishment of an industry recycling alliance will act as a solution to many of Taiwan's problems related to processing waste PV panels. As for Europe, TSGC has received invitations from Belgium's Wallonia Foreign Trade and Investment Agency (AWEX), Switzerland's official agencies, and local companies, and expects to establish a European subsidiary at the end of 2023. The export of related technologies to the European market will solve the challenges of recycling waste PV panels in these countries.

TSGC co-founder and CEO Andrew Hung

Photo: DIGITIMES

PV Circulator, a recycling equipment for end-of-life solar panels, utilizes physical and fully automated methods to achieve a nearly 100% recycling rate, 95% energy saving and 99% emission reduction

Photo: Company