In 2022, the demand of semiconductor chips is facing an uncertain outlook, apart from the strong surge in orders of previous year. Especially in consumer electronics sectors, the market seems to be lessening demand and showing slowdown. But the power management IC (PMIC) and 5G radio frequency (RF) silicon chips are maintaining continuous strong growth. Driven by multiple applications such as automotive, industrial automation and control systems, PMIC remains high and continues with high attention. The demand for electric vehicle (EV) power charging stations, battery charging control and USB power transition are all relying on PMIC chips to provide the outstanding performance.

Seeing the huge growth of electric cars and electric vehicle supply equipment (EVSE), the IC chip makers are looking for the innovative production solutions for pushing a quick ramp-up of the production scale. The fan out panel level packaging (FOPLP) technologies have the potential to ease the current chip shortage concerns with the key benefits of cost reduction and heat dissipation features. The technology and equipment suppliers for FOPLP continuously are becoming technically more demanding.

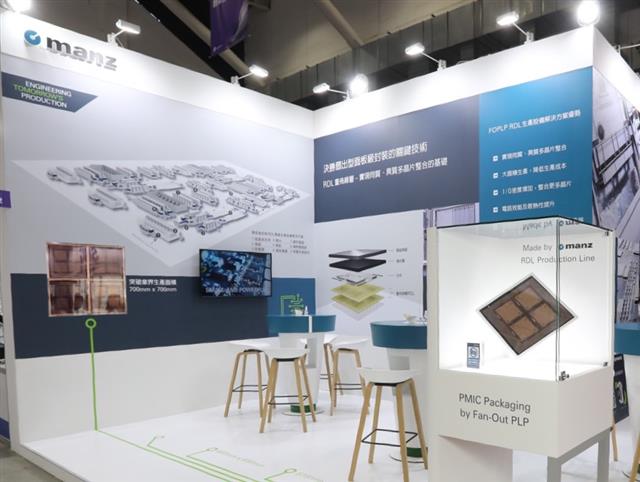

Manz AG as one of the key players of wet chemistry and Cu plating process equipment showcases a major technical breakthrough of FOPLP RDL equipment in 2022 SEMICON Taiwan exhibition. The Re-Distribution Layers (RDL) of FOPLP processes do matter while the high volume production phases kick-in. And these solutions are rapidly transforming FOPLP as the prevailing technology in advanced package sectors.

This interview with Robert Lin, General Manager of Manz Asia, takes a closer look at the new development of FOPLP technology and equipment. The current line width and spacing (L/S) specification is reaching to 10/10 to 25/25µm ranges, which is fully fitting the requirements of PMIC production in semiconductor industry. The previous demonstration of the process and equipment was welcomed by the global IDMs and quickly to set the mass production planning in 2023. At this moment before the end of 2022, Manz AG is scheduling to work on the process machinery moving into the customer's factory and fine tune the production parameters. This is a key milestone in a successful manufacturing of FOPLP technology.

The IDMs are pushing the FOPLP volume production phase to address increasing chip manufacturing and boosting supply. On the other hand, Taiwan OSAT and major IC design vendors also keeping up the pace with verification testing and FOPLP adoption. Manz is incorporating with supply chain partners and material suppliers to make industry continuing its robust growth on improving the yield rate.

Enabling supply chain collaboration to accelerate the adoption of FOPLP

Talking the progress of FOPLP process development for PCB and panel makers, the major Taiwan display panel OEM/ODM manufacturer has announced starting to provide the FOPLP manufacturing services to customers. And there are several Taiwan OSAT vendors built the new production lines in the current fabs through Capex investment for preparation of volume production in 2023. This is encouraging for Manz FOPLP technology development and having an ambition to win the project, Lin highlights.

Facing the diverse needs of the market, especially the trending heterogeneous integration has become one of the important solutions for the continuation of Moore's Law, Manz will actively expand the reach of its Total Production Solutions to help customers. The current Manz's roadmap is continuing to go to optimum production and provide solutions to overcome major issues such as warpage challenges with the integration of the process equipment form supply chain partners .

In the SEMICON booth, Manz's demonstration is the state-of-the-art production design of 700 x 700mm in surface areas. There are several production samples in 340 x 340 mm using stainless steel substrates. The production process has been proven and delivered to customers for pre-production verification. Furthermore, the use of stainless steel substrates has convincing performance results to increase yields. This is a compelling evidence to reach the volume production for FOPLP technology.

Targeting 700 x 700 mm process areas as an industrial production standard

There are currently three popular sized for the FOPLP process including 515 x 515, 600 x 600 and 700 x 700 mm. Considering the benefit of production efficiency, the process dimension of 700 x 700 mm is the bigger the better. It will produce the silicon die counts equal to four 12-inch wafers, or nine 8-inch wafers. This will help to achieve the goals of miniaturized packaging and lowering costs while the yields rise. Lin sees 700 x 700 mm in process dimension a great potential for the industrial standard.

Manz has been investing FOPLP RDL technological innovations since 2016. The process verification is successfully verified by the precision adjustment of Cu-plating process applied in large area of redistribution layers and overcome the major technical challenges including uniformity of electroplating pattering, high resolution and high electrical connectivity. This development supports key customers to prepare the sample devices and obtains certifications of mass production. The coming actions for Manz will actively expand the reach of its Total Production Solutions to provide the services to build from single equipment to automated production lines with certified manufacturing processes. With the high performance of FOPLP RDL production systems, Manz is seizing the opportunities with continuous innovation in advanced packaging applications.

Manz AG as one of the key players of wet chemistry and Cu plating process equipment showcases a major technical breakthrough of FOPLP RDL equipment in 2022 SEMICON Taiwan exhibition